Whenever the machine is in a down state, a downtime event is automatically created in the system. Further, if a downtime code is assigned to the period, whether manually or automatically, the “type” of downtime code that is assigned can influence the calculation of OEE for that period of time.

- If the resulting downtime period is not assigned, it is categorized as “Unassigned”, it is treated as Unplanned Downtime, and the Machine Operating Time is reduced, causing Availability to be reduced.

Note: When the Downtime Tracking application is not active for the machine, then this is the only type of downtime possible.

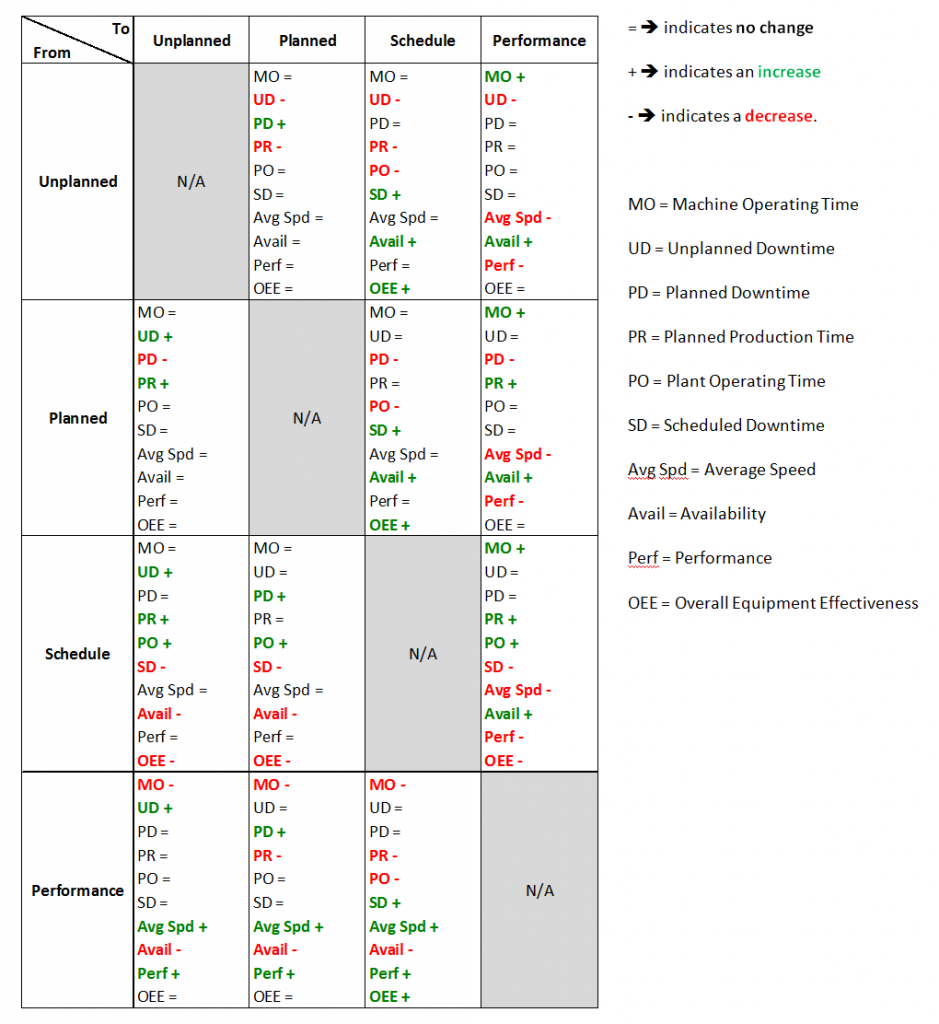

- If the resulting downtime period is assigned with a downtime type of “Scheduled”, then it is defined as Scheduled Downtime, and both the Machine Operating Time and Plant Operating Time are reduced by the amount of time of the downtime period. This is consistent with OEE industry standards, in which Scheduled Downtime is not considered in the evaluation of OEE. If the downtime type is changed to “Scheduled” by manual re-assignment from any other type, then OEE components are affected accordingly. Please refer to the Downtime Transition Matrix below.

- If the resulting downtime period is assigned with a downtime type of “Planned”, it is defined as Planned Downtime, and both the Machine Operating Time and Planned Production Time are reduced by the amount of time of the downtime period. In the cases when the downtime type for this period was previously either unassigned or assigned as the “Unplanned” type, then Machine Operating Time and Availability remain unchanged because the downtime is still considered an Availability Loss. If the downtime type is changed to “Planned” by manual re-assignment from either “Scheduled” or “Performance”, then OEE components are affected accordingly. Please refer to the Downtime Transition Matrix below.

- If the resulting downtime period is categorized with a downtime type of “Performance”, then it is defined as Performance Loss, and the machine’s Average Speed is reduced causing the Performance component of OEE to be reduced. If this assignment was for a period that was previously assigned to a different type, or unassigned, then the Machine Operating Time would be increased by the same amount of time, and OEE components are affected according accordingly. . Please refer to the Downtime Transition Matrix below.

- If the resulting downtime period is assigned with a downtime type of “Unplanned”, then it is defined as Unplanned Downtime, and the Machine Operating Time is reduced causing Availability to be reduced. In the cases when the downtime type for this period was either previously unassigned or assigned as the “Planned” downtime type, then the Machine Operating Time and Availability remain unchanged because the downtime period is still considered an Availability Loss. If the Downtime Type is changed to “Unplanned” by manual re-assignment from either “Scheduled” or “Performance”, then OEE components are affected accordingly.