Machine waste is calculated by three main factors: Good Material, Bad Material, and Total Material.

Total Material is a measure of all (total) material produced by the machine.

Good Material is calculated by summing the machine’s good material output – the material that is deemed to have acceptable quality.

Bad Material can be determined by subtracting the Good Material from the Total Material for a discrete time period. This is the amount of waste (Bad) material that has been produced by the machine.

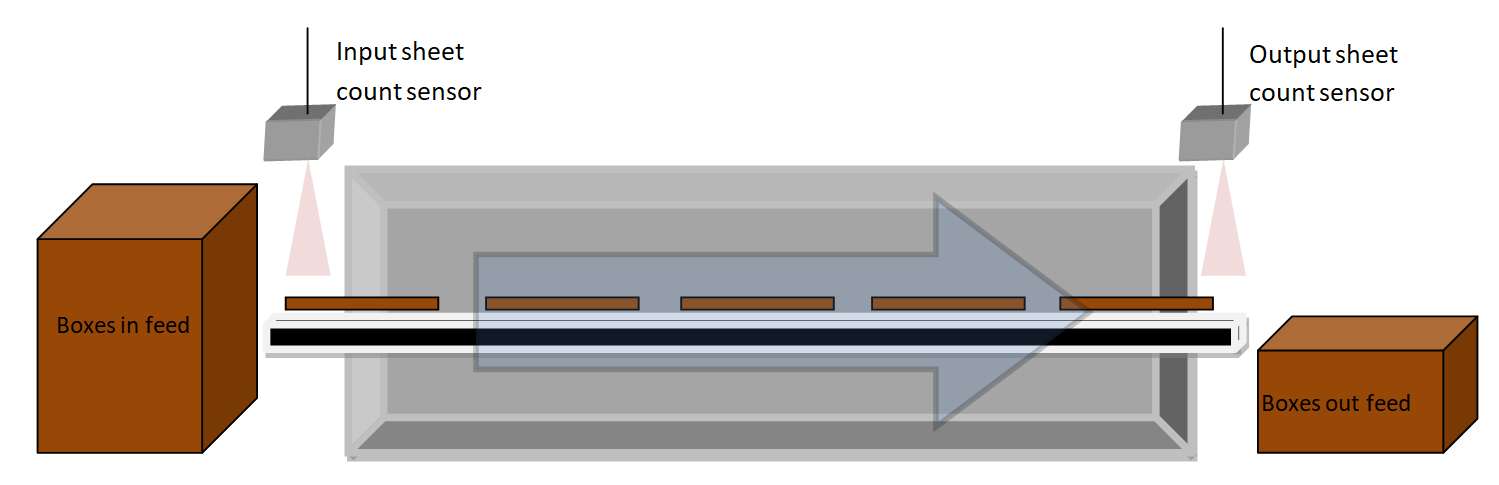

In order to best calculate these values, we may rely on sensors placed strategically along the machine material flow to count the material produced. For certain machine types where the machine’s control system automatically discards waste material, counting the material input and output separately is sometimes used to determine waste, such that waste then becomes the difference between input and output material.

Such a machine with well-placed material count sensors allows for a reasonable computation of OEE and waste material produced by the machine.

Waste = input – output

In order to collect the data, we need only two of the three measurements: the third can be derived from the other two.

Here are four common scenarios:

- Only total material is counted – there is no Good/Bad Material count, and hence, Quality cannot be derived from the machine data.

- Both Total & Good Material are counted – Bad Material equals Total – Good Material.

- Total & Bad Material are counted – Good Material is equal to Total – Bad Material.

- Good Material and Bad Material are both counted – then Total Material is equal to their sum.

© 2024 ei3 Corporation. Content of this web page is proprietary to ei3 Corporation.