When a new machine has been brought online for data collection, it’s important to validate the information being collected to ensure that it is correct.

If a machine check is not performed, it can result in several problems with machine data coming across on reports, downtime tracking, or other aspects of ei3 data collection.

To perform a thorough data collection validation check, follow each of the items listed below. Before performing these data validation techniques, wait at least 24 hours after a machine data collection job has been started to allow for data to populate across the machine.

1. Check machine up and down time

If a machine’s up and down state (material produced, temperature, other machine state) is not accurate, this is a sign that the data collection job is impacted.

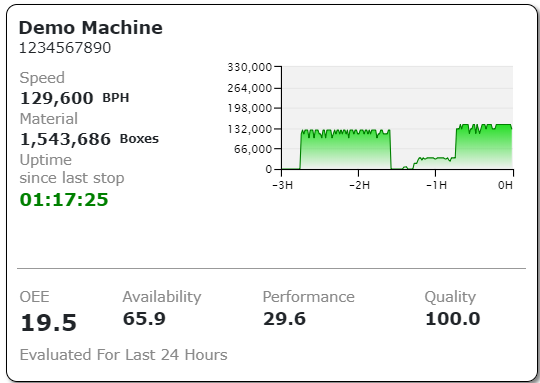

An easy way to check this is to verify that the machine badge on the Overview page is displaying proper information for your machine.

Checking the Uptime since last stop (in this case 1:17:25) is a simple way to verify that the machine data is being read properly by ei3.

2. Check OEE numbers

After 24 hours of machine run time, the machine badge OEE values (shown on the Overview page) should display information on machine Availability, Performance, and Quality. If these numbers aren’t properly showing OEE data, there may be an error in your machine configuration. This can be, but is not limited to: shift schedule errors, machine max speed set incorrectly, or incorrect data points.

3. Downtime Tracking: Verify machine uptime and downtime are displaying correctly

If your machine has Downtime Tracking enabled, it’s best to check the Downtime Tracking > Assign page to ensure that the machine’s up and down states are being properly tracked.

If the histogram is not displaying proper data, there may be issues with the data collection for that machine.

4. Speed units per minute/per hour

If a machine’s data calculations are set incorrectly, all charts and machine information will be impacted. Make sure that a machine meant to run at a certain speed in units per hour is not set to units per minute, and vice versa. If you are an admin you can check this by navigating to Admin Tools > Machines, then clicking the Edit icon ![]() to open the Edit Machine page.

to open the Edit Machine page.

5. Set the correct minimum production speed

Every machine should have a minimum production speed, which is used to determine if the machine is running or not. If this is set incorrectly, machine data and OEE calculations will be incorrect.

If you don’t know your machine ‘s minimum speed, it should be set to 1.

6. Look at actual machine data on the Dashboard

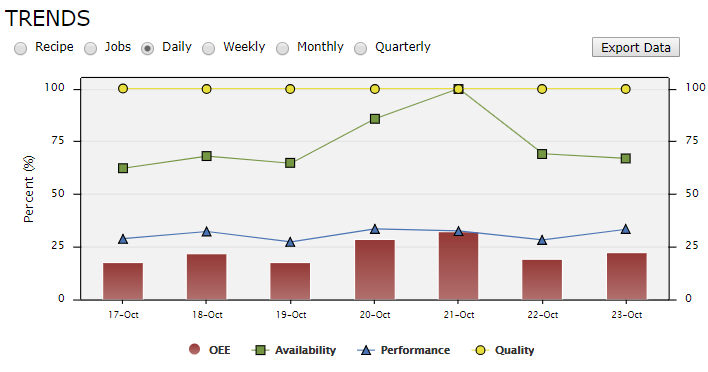

After 24 hours, machine data will populate to charts on the ei3 web application such as the Remote Monitoring productivity charts or from Dashboard tab. This is a surefire way to check machine data over time and to make certain that it is collecting properly.

You can also export the last 24 hours of machine data collected every minute from set data points using the Export Data function available from the Dashboard page when viewing the Trends chart from the ‘Daily’ chart setting.

7. Check that machine counters increase

When a machine is running normally, it will typically be running a counter of some kind to monitor the machine production rate. This can vary by machine, and may include but is not limited to such counts as a material mode, parts counters, a shot counter, etc. By checking to make sure these counters are behaving correctly, machine data can easily be validated.

8. Make sure that the machine is set to the correct time zone

If your machine is not set to the correct time zone, the shift schedule will be impacted, which will cause OEE values to be incorrect. You can check if your machine is set to the correct time zone by running a Current shift report (found in the Reports menu). If the start and end times don’t line up with the shifts on your machine, it can mean that the machine time zone is set incorrectly, or that the shift schedule is not properly configured. Both of these will result in improper machine data and OEE calculations.

9. Ensure that the machine schedule is completely filled out

When creating a shift schedule to apply to your machine, make sure that the shift schedule is completely filled out. If there are time periods for which the machine will not be running, mark as No Production to exclude these times from OEE calculations. It is important that the shift schedule is completely filled out. Gaps in a shift schedule will cause problems with OEE calculations and reports.