Introduction

Emerald PLC controls up to 32 servo axes using SERCOS II master interface and compatible Emerald drives. The earlier models communicate over serial interfaces and the later models communicate over TCP/IP with the outside world.

The EMC-2100 is a redesign of EMC-2005 version of the Emerald Series Motion Controller. Its features are Removable Memory Card Reader and Ethernet w.r.t. EMC-2005. The controller is programmed using our comprehensive Emerald Motion Programming Language (EML) and powerful new Emerald Development Environment (EDE) software tools for the PC.

Hardware

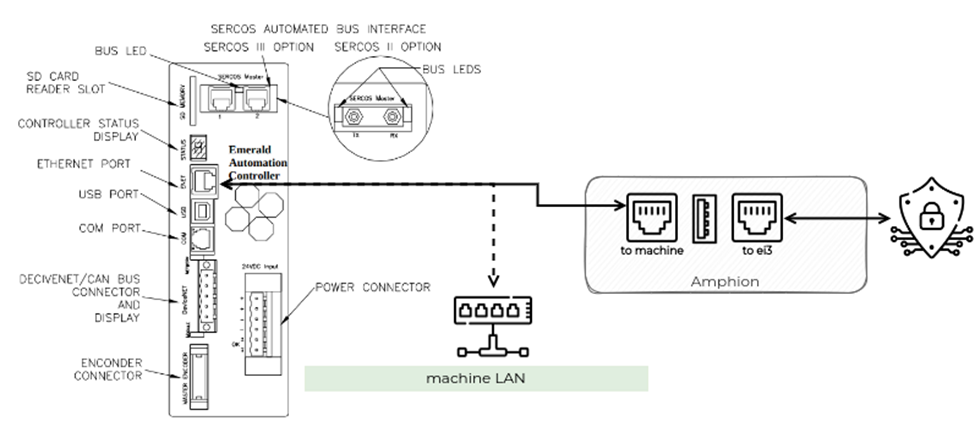

Emerald PLC is a stand-alone control. We use a direct Ethernet connection and we communicate over TCP/IP protocol.

Wiring diagram

The machine LAN topology can be as simple as a single cable between the Amphion “to machine” port to the Emerald ethernet port (not the Servos III ethernet ports), or it might be plugged into a machine LAN switch/router.

Collector

In ei3 applications, the collector type used to connect to Emerald PLC is Emerald – PLC (Amphion), as the name suggests this collector runs on Amphion only.

Device

The following information from the device configuration will be used to connect to the PLC:

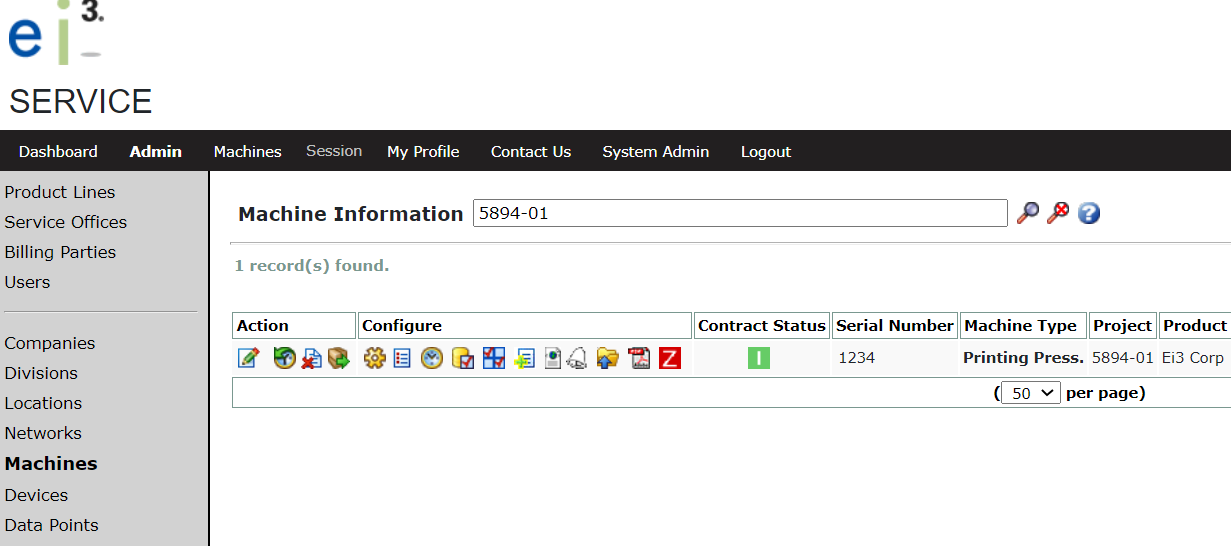

To add a new device, login to your service portal, click on Admin > Machines and search for the machine you would like to add the device for.

Then click on the gear ![]() icon under the configure column to go to the devices section for this machine.

icon under the configure column to go to the devices section for this machine.

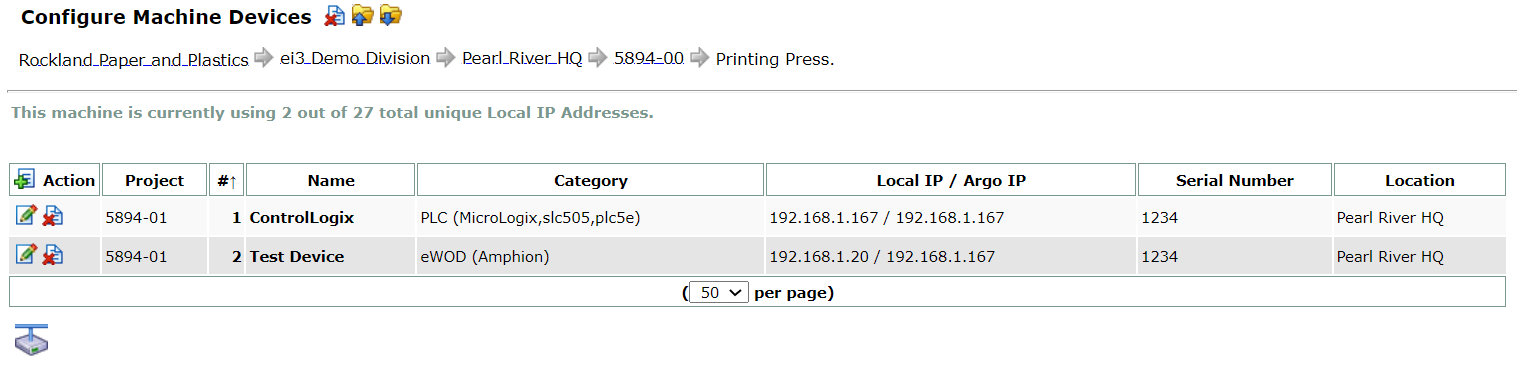

Click on the new ![]() icon to add the new collector.

icon to add the new collector.

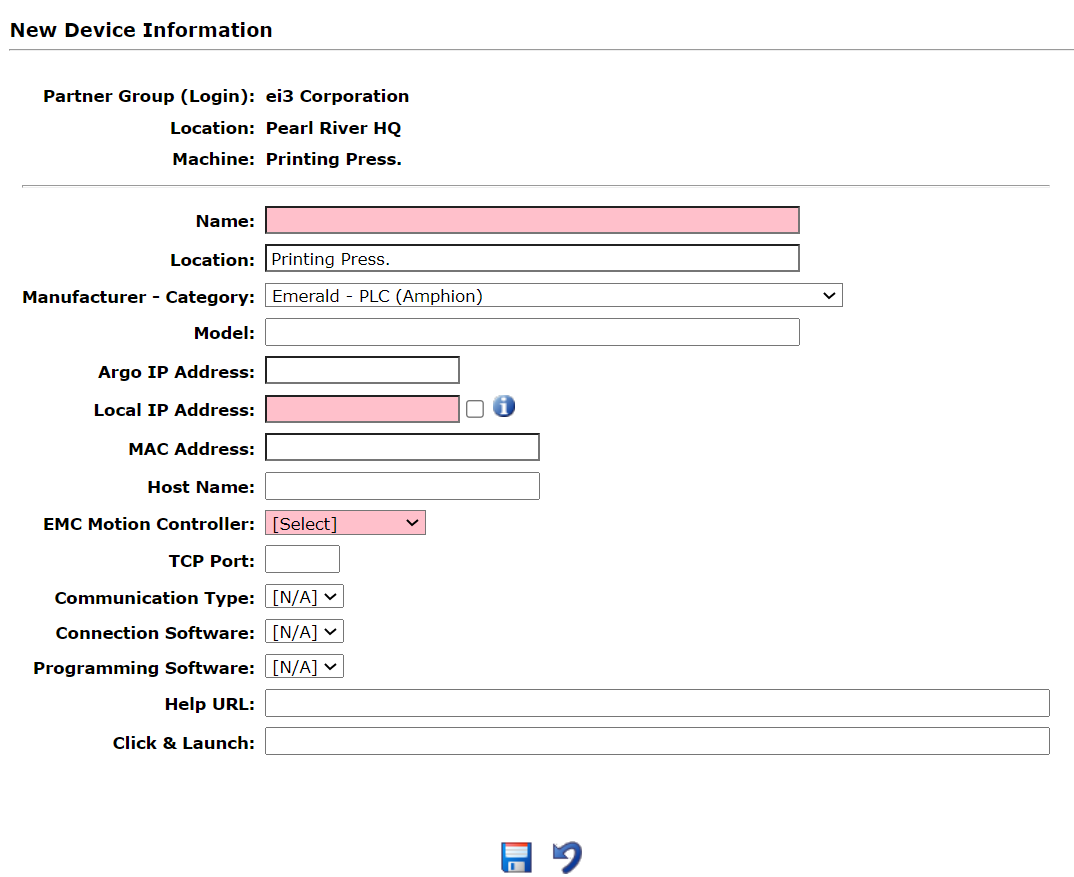

Enter a name for the device and then select the Manufacturer – Category to be Emerald – PLC (Amphion).

The Local IP Address is the IP address that the Amphion will use to connect to the Emerald PLC in the Machine LAN.

EMC Motion Controller must be one of the following:

- EMC200

- EMC1000

- EMC2005

- EMCMAX

- EMC2100S2

- EMC2100S3

- LMC400

- LMAX

- LMC400B

Data Points

Data point tags are not available for Emerald PLC, meaning that we cannot access data points/variables by name (or any other meaningful id/key) used in PLC programs or memory.

However, the data is accessible as a single value or array by a 32-bit memory map address.

The addresses shall be set or given by the client (or machine manufacturer) and provided as a string representing a hexadecimal 32 bits address.

Data Point example

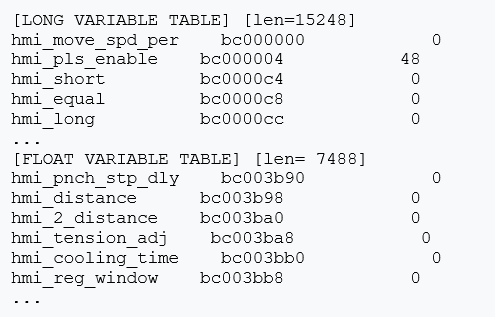

The machine operator or manufacturer might provide a list of tags similar to:

With this information, ei3 will create data points of numeric type using the bcxxxx values above as the read addresses.

Sometimes some variables are arrays, if an array contains 48 successive values, we will need to create 48 points, and increment the address by 8 (as float are 64bits 8×8), as we do not support arrays on the collector side.

Adding Data Points

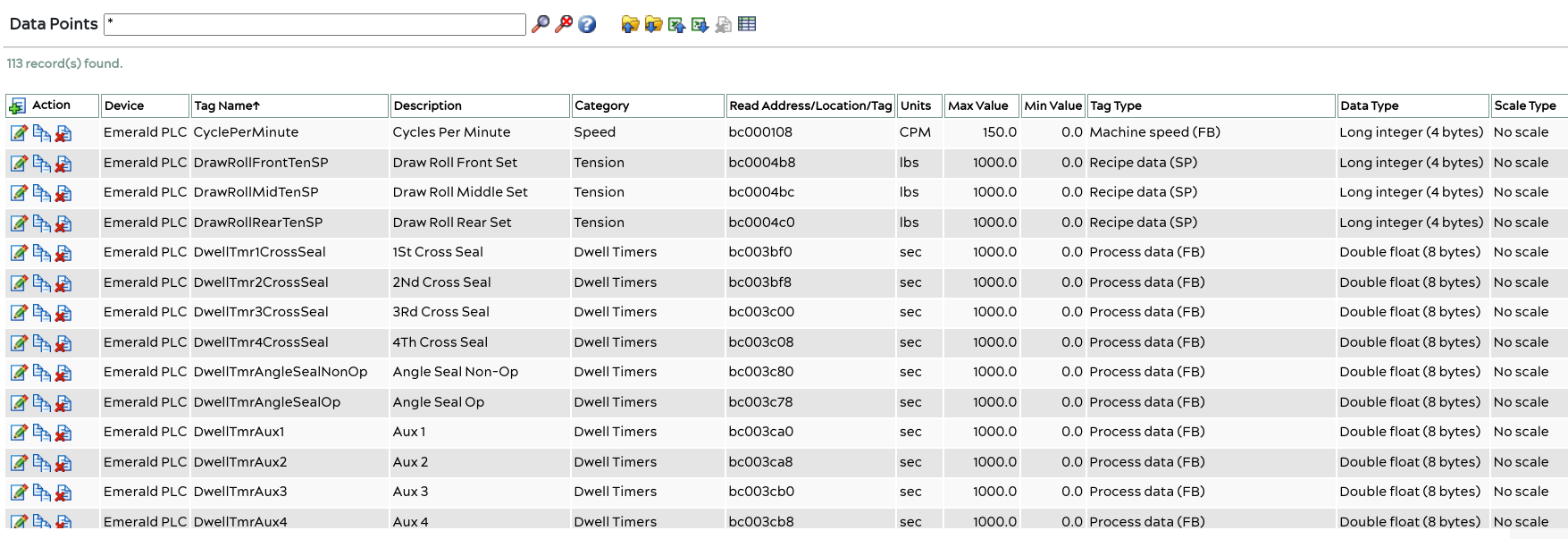

Once logged into ei3, click on the gear icon on the top menu bar, go to Admin > Data Points. Below is an example list of data points using the Emerald PLC.

- If you would like to create individual data points, click here. You may also want to see this article, explaining how to fill out the information required for a new data point.

- If you would like to add multiple data points at a time using Excel, click here.

- If you would like to add multiple data points at a time using XML, click here. The XML template is also useful if you would like to copy data points from one machine to another.

© 2024 ei3 Corporation. Content of this web page is proprietary to ei3 Corporation.